1-877-PIPEMAN

1-877-747-3626

Hours: 7 AM to 4:00 PM Mon-Fri PST

Support

Our Frequently Asked Questions below contain valuable information on helping you find the right product for your needs. View pipe OD charts, manuals, install sheets and certifications available in PDF format.Pipe OD

ChartRPM

TableTM-1 Pro

Parts ListTM-1 Pro

ManualWheeler Rex 8100 Manual

Jet Swet

Install SheetWassi

Install SheetHot Dam

MSDS

Hot Dam Gel MSDS

Insta-Clamp Install Sheet

PS 3425

Install SheetNSF vs. UL Certification

Cold-Shot

ManualArctic Freeze Manual

Quik-Freezer Manual

JCM HDPE

Guide

Frequently Asked Questions By Product Type

Top Questions

- What is Hot Tapping?

- What is Line Stopping?

- How do I fix a leak on a copper solder joint without shutting down or draining the system?

- How can I isolate a line to add a new line or valve?

- What type of pipe freeze kit will best meet my application?

- Do you have a hot tap saddle made just for copper pipe?

- Is a 1/2" outlet available for hot tap saddles or machines?

- What is the difference between using a service saddle and a tapping sleeve?

- Why can’t I choose next day air shipping on your website?

- My question isn't answered here. How do I submit a question?

Hot tapping is also known as wet tapping. It is a way to tap into a water line while it is under pressure and add a line, drain the system or add a Thermowell or sensor. You place a hot tap service saddle or sleeve onto the line. You add a valve and test the connection under pressure with a hydrostatic pump. Then you place the hot tap machine onto the value through a water tight packing gland, open the valve and lower the cutter and retention pilot down until it touches the pipe. You then drill into the pipe manually or with an electric or air driven unit that cuts a hole in the pipe. The retention pipe grabs the cut out coupon so it doesn’t fall down into the pipe where it could cause a problem down he line. You then retract the cutter and pilot up into the hot tap machine, close the valve and you have completed a hot tap.

When you can’t stop the flow in a line and need to do a repair without draining the system or causing a long shut down, a line stop works well. Line stopping is similar to hot tapping in that you will be tapping into a live line under pressure. You will then remove the hot tap machine and place a line stop machine onto the valve. A line stop machine has rubber bladders that act like line plugs that will expand after being lowered down into the pipe. Once the flow is stopped, the repair can be performed. Completion of the job has the line stop machine retracted, removed and shutting the value off. A completion plug setting tool is placed on the valve and screws a completion plug down into the outlet. You remove the plug setting tool, remove the valve and add a cap and your job is completed.

There were not a lot of inexpensive options for fixing a leaking solder joint without shutting down the system until the Insta-Clamp was born. The Insta-Clamp can fix a 1/2" to 4.00" copper solder joint leak in just a few minutes with its unique step-up NBR Waffle gasket. It allows you to do a permanent or temporary repair in minutes without draining or shutting down the system or using a lot of time and materials.

This can be achieved through several different methods. The most popular way if the water in the line is not flowing is pipe freezing. Pipe Freeze Kits using CO-2 are an inexpensive way to get the job done when draining the system is not an option. By pipe freezing you can place a 7000 PSI ice plug on one or both sides of your repair, complete the job and just let the ice plug thaw out. It just requires a pipe freeze kit and dip tube CO-2 cylinders.

The second way is a little more complicated and expensive. If you can’t shut off a valve and stop the flow a Line Stop will allow you to accomplish the same task. It requires Hot Tapping the pipe and then doing a Line Stop. This requires a Hot Tap Machine, Valve, Hydrostatic pump, Line Stop Machine and Saddle.

This depends on your application and size of the pipe. There are two types of pipe freeze kits. The most popular for 1/8" to 2.00" pipe is the CST-2 Cold-Shot Pipe Freeze Kit by General Wire. It comes with dual pipe freeze capability that fits into small places and uses only a 20lb dip tube CO-2 cylinder.

The second most popular style is the freeze jacket style like the economical Arctic Freeze Kit (1/4" to 6.00" pipe) or the more industrial model, the Qwik-Freeze Kit (3/4" to 8.00") The jackets take more room to use but can go beyond 2.00" pipe. They can also freeze the line with about a 20-30% glycol mix.

Another popular style is the The Accu Freeze kit (AF-1000) Liquid Nitrogen Pipe Freezing System which can freeze lines up to 12.00".

There are not a lot of options for hot tap saddles or sleeves for copper tubing (pipe). We carry the PowerSeal PowerStop 3425 S/S Hot Tap Sleeve with exact fit NBR gasket. The 3425 has sizes from 3/4" dia to 8.00" dia with male IP outlets from 3/4" to 4.00" including size-on-size from 3/4"x3/4" to 4"x12"x4". The 3425 has a full circle gasket that eliminates all electrolysis on copper application. We also have in limited sizes and applications bronze and ductile iron wide strap service saddles that work with copper pipe too.

We offer products for mainly the Waterworks industry. The hot tap supply industry dictates that 3/4" and above is what they manufacture. However 1/2" outlets can be special ordered for several styles if needed. Many companies use a 3/4" outlet and only make a 1/2" hole with their cutter for flow or simply use an inexpensive reducer from 3/4" to 1/2".

A service saddle is a smaller more economical unit that uses an O-ring gasket to seal the saddle and the pipe. There are four basic styles: Single bale, Single wide strap, Dual bale and Dual wide strap. The bale style works best on harder pipe like Carbon Steel, Ductile Iron and Cast Iron. The wider strap units work well on softer metals like copper and PVC.

We prefer you call us if you need your products by a certain date. We want to ensure you get what you need when you need it, and strive to make this happen at the lowest cost to you. If we offered next day shipping and you chose that method, but were within one day of transit through ground shipping, it would be difficult to adjust your total. We also want to verify availability of the product to correctly assess which mode of shipping would best suit your needs. The online shopping cart does not enable us to serve you as well as we can in person. To calculate your shipping costs properly for expedited shipping, we prefer to take your order by phone at 1-877-PIPEMAN (747-3626). This ensures the lowest UPS rate if you need expedited shipping.

Questions By Product Type

Question: With so many products to choose from, how do I know which tapping sleeve I need?

Answer: Knowing which tapping sleeve to use can be difficult. If you don’t know which product to buy, please call us Toll Free at 1-877-PIPEMAN (747-3626) and let us help you. To correctly assess which product will meet your needs we need to know several things:

1. Type of Pipe: (carbon steel, PVC, copper, Ductile Iron, C900 ACP and others).

2. Correct Pipe O.D.: (some saddles have range and some are exact fit).

3. Contents in the Line: (Saddles do offer several types of gaskets for different applications).

4. Temperature and Maximum PSI: (water sewer and air/gas lines have different ratings).

5. Location of the Line: (above/below ground, inside/outside and type of soil can make a difference).

Question: We are interested in your powerseal hot tap sleeve to tap into an existing copper tower water line without draining the system, and minimal shut down time. I would like more information on how the tap is actually made after the sleeve is installed.

Answer: The PS 3425 SS Hot Tap Sleeve is the premier tapping saddle for copper pipe. They are available in 3/4"x3/4" to 8"x3" and size-on-size i.e. 2"x2" 4"x4" etc. To use this or any other hot tap saddle or sleeve you need a Hot Tap machine. There are portable units that can do a 3/4"-2.00" tap or our professional models that can go to 6" taps. They range from $649.00 and up for the portable units and $3,995.00 and up for the professional model. Instructions: You place the saddle/sleeve on the line and add a valve (ball valve, gate valve. Corp stop). Then you test the saddle for fit and pressure retention with a hydrostatic test pump which goes through the valve. The hot tap machine has a packing gland which seals at the valve. Then you tap the pipe using the hot tap machine that lowers a hole saw and pilot with retention wires to capture the cut out metal or plastic coupon. When done with the tap you retract the assembly up into the hot tap machine and close the valve. Job completed ready for draining or adding a line etc.

Back to Top

Question: What is the difference between the JCM Service Saddles - Models 402, 404, 406 and 408?

Answer: The JCM 402 and the JCM 404 utilize the heavy duty double strap saddle body with corrosion resistant shop coat primer. The 402 is furnished with two electro galvanized straps (bales) for 2.00"-12.00", on sizes 15.20" and larger the 402 incorporated two fabricated steel straps. The 404 is furnished with two wide stainless steel straps. The JCM 406 and JCM 408 utilize the heavy duty double strap saddle body with a fusion applied, heavy resilient plastic coating. The JCM 406 is furnished with two wide stainless steel straps. The model 408 is furnished with two coated steel straps (bales).

Back to Top

Question: When would I use a weld on fitting instead of a bolt on fitting?

Answer: There are many reasons why a weld on fitting would be used instead of a bolt on fitting. First and foremost is cost if the application allows welding. Secondly is temperature or PSI requirements. Normally weld on fittings can take a higher PSI and temperature.

Question: Which type of weld on fitting do I need?

Answer: Which style of weld on fitting you need may depend largely on the code requirements in your area. For instance, some areas have codes which prohibit vertical welds onto the existing pipe, so those styles would not be acceptable, yet other areas have codes that require a full circle body. It really depends on what is allowed or disallowed in that area.

Back to Top

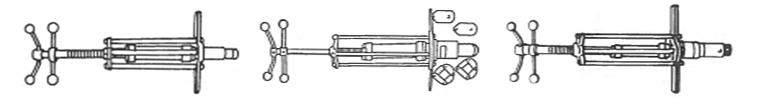

Question: Which Hot Tap Machine would meet my needs?

Answer: It depends largely on what size tap you need to perform and how you plan on using your machine. For commercial use, and for taps up to 6.00", the TM-1 Pro Series is the model that will hold up to daily use. If you need to perform taps 2.00" or smaller and will only use the machine on occasion, the Wheeler Rex 8100 and the Wheeler Rex 8200 are great manual tapping machines. The Wheeler Rex has additional adapters available for matching up with unique thread patterns where the TM-1 and Wheeler Rex are designed with NPT threads only.

Question: What kinds of pipe can I tap with the TM-1 Pro and the Wheeler Rex 8100 / 8200?

Answer: All of our Hot Tap Machines can tap into: Copper, Steel, PVC, C900, Ductile Iron, Cast Iron, Abestos Cement and other types of pipe. Each type of pipe may take different hot taps cutters depending on its softness or hardness.

Question: How big an outlet can your Hot Tap Machines tap?

Answer: The TM-1 Pro can tap from 3/4" - 4.00" NPT Taps and 6.00" Standard or MJ Flanged taps. The Wheeler Rex 8100 / 8200 units can make NPT taps from 3/4" - 2.00".

Question: Can I do smaller flanged taps with the TM-1 Pro?

Answer: Yes, we provide a 4x4 companion flange for flanged taps with the 4.00" NPT Adapter. You can also buy smaller companion flanges such as 2.00", 2-1/2" and 3.00" companion flanges if a flanged tap is desired in these sizes. It just screws on to the provided NPT Adapter.

Question: Why can’t your competitors do a 6.00" tap with their units that look similar to the TM-1 Pro?

Answer: Our competitors use an inferior and smaller boring bar attachment device that does not allow for larger taps. Our unit is built by professionals for professionals and has proven successful in the field for over 17 years.

Question: Can I use a hand drill on the Wheeler Rex 8100 / 8200 Hot Tap Machines?

Answer: No, the nylon bushing in the unit will warp or melt if spun to fast. This is a an easy to use manual ratcheting hot tap machine.

Question: Can you use the Wheeler Rex 8100 / 8200 with corp stops?

Answer: Yes, Wheeler Rex has a few Mueller 110 corp stop adapters in 1.50" and 2.00".

Question: Do you have any advanced technical support available besides the salespersons at your company?

Answer: Yes, we have several. Our service side company technicians can answer any questions you may have about using the equipment and it’s applications on different types of pipe.

Back to Top

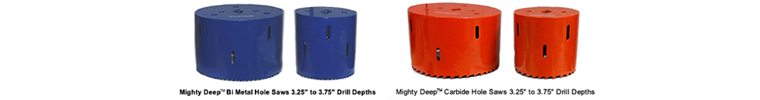

Question: When should I use a Bi Metal Hole Saw?

Answer: Bi Metal hole saws are recommended for cutting copper, steel, aluminum, brass, cast iron, plastic or wood.

Question: When should I use a Carbide Hole Saw?

Answer: Carbide hole saws are recommended for cutting cast iron, ductile iron, wood laminates, fiberglass, plywood or tile.

Question: What is the proper rpm for cutting wood, steel or other types of material?

Answer: Please see our Blu-Mol RPM Chart for best practices. Always wear proper safety gear when using hole saws.

Question: Does Blu-Mol make different kits for various types of jobs?

Answer: Yes, they have unique Blu-Mol Hole Saw Kits just for electricians, locksmiths, handyman, plumbers, industrial work and more.

Question: When should I use a STHS Hot Tap-Line Stop Carbide Tipped Cutter?

Answer: These are made specifically for hot tapping and line stopping with the TM-1 Pro Hot Tap System. They have a standard holesaw back-plate that can also be used with a standard or heavy duty arbor. They work well with ductile and cast iron pipe.

Question: What is the difference between your Relton Carbide Cutters and the Blu-Mol or TapMaster Carbide Hole Saws?

Answer: The Blu-Mol and TapMaster Carbide hole saws have carbide tips, which allow for greater heat and wear resistance than bi-metal saws. The Relton Carbide Cutters have brazed carbide teeth which have great endurance, can be sharpened, and can be replaced if needed.

Question: Can you make the Relton Carbide Tipped Hole Saws for any other sizes? What if I need special inside diameter?

Answer: Yes, Relton can make diameters to 60" and cutting depths to 48". Relton can make just about any combination of Pipe ID and OD as needed.

Question: Why are the Relton Carbide Tipped Hole Saws more expensive than standard carbide hole saws?

Answer: The Relton Carbide Tipped Hole Saws are commercial quality made for manufacturing and when being used often. They outlast a Bi Metal hole saw 50-1 to 200-1

Question: Can you replace the Relton Hole Saws brazed on carbide tips or resharpen them?

Answer: Yes, both can be done very inexpensive cutting down the real cost of ownership.

Question: Can I use my standard arbor with the Relton Carbide Tipped Hole Saws?

Answer: No, not unless you have a special order. Then we can have the standard hole saw back-plate made.

Question: Why are the TapMaster Bi-Metal and Carbide DoubleStack, TripleStack, QuadStack Hole Saws so expensive? Can I use my standard arbor with these?

Answer: The TapMaster Bi-Metal and the TapMaster Carbide Hole Saws are cut and perfectly welded together so they cut straight and round. There is not a major hole saw manufacturer currently making a cutting depth over 2.00" yet there is a big need for Xtra Deep hole saws. We provide these at a reasonable cost mainly for our hot tap and pipeline customers. These Hole Saws use the standard arbors made by all major manufacturers

Question: Do I need to use Pilot Drills with dual retention wires when I hot tap?

Answer: It is highly recommended that you use TapMaster Steel Pilots with Dual Retention Wires for Hot Tapping because the retention wires grab/catch the coupon/cookie so it doesn’t fall down into the pipe and block the line or jam a valve. That could be quite an expensive repair. These are made especially for the TM-1 Pro machines.

Back to Top

Question: Why does the line stop sleeve for 1-1/2" pipe have both 1-1/2" and 1-1/4" outlets?

Answer: The different outlets accommodate different models of Qualitech line stop machines, which are both capable of stopping 1-1/2" lines. The Qualitech Model 1251 stops 1-1/4" and 1-1/2" lines through a 1-1/4" stopper nipple, while the Model 2001 stops 1-1/2" and 2.00" lines through a 1-1/2" nipple.

Question: Do the QT Stopper Bolt-on Line Stop Saddles take special equipment to use?

Answer: Yes, they require a Qualitech Line Stop Machine. Line stopping is one of three great way to grow your commercial plumbing business besides hot tapping and pipe freezing. The Qualitech line Stop Machines are available for 3/4" through 6" line stops.

Question: Do you have these for different kinds of pipe?

Answer: Yes, we stock them for Copper and Steel/PVC size pipe. They are also available for Ductile Iron and Abestos Cement pipe.

Back to Top

Question: What are Qualitech Line Stop Machines used for?

Answer: There are times when you just can’t drain the system in a facility. Line Stopping allows you to block off the water so you can remove a section of bad pipe or stuck valve and replace it and then resume service without a major interruption. You complete a Hot Tap through the line stop saddle and then use the Qualitech machine to block off the water while the repair is done and then remove the machine and valve, insert a plug, cap it off and your job is complete.

Question: Does the Qualitech line stop equipment perform the tap that will allow the plug into the line?

Answer: No. The line stop equipment is only for inserting and removing the stopper plug, then installing the completion plug to cap the outlet on the stopper nipple. Any tapping equipment can be used.

Question: Do you have weld-on fittings for steel pipe instead of Bolt-on saddles?

Answer: Yes, we carry the Qualitech carbon steel weld-on line stop fittings with plug and cap.

Back to Top

Product Description: TapMaster Line Stop Sealing Elements Cups are used for doing a "Line Stop". This is the process of tapping into a live water line then inserting the urathane cups or bladders that hold the water back so a fitting or valve may be changed when you can’t shut-down or drain the system. Tapmaster Line Stops cups are designed to work with Schallert Line Stop folding heads. See Tapmaster Leading Edge Sealing Element Line Stop Cups.

Back to Top

Question: Which pipe freeze kit do I need?

Answer: Three of our pipe freeze kits use CO2 and one kit uses nitrogen for pipe freezing. Our CO2 kits include the Cold-Shot, the Arctic Freeze and the Qwik Freezer kit. The portable Cold-Shot kit can freeze lines 1/8" to 2". The Arctic Freeze kit can freeze lines from 1/4" to 2.00" through 1/4" to 6.00". The Qwik-Freezer kit is a more commercial grade CO2 pipe freezing system that can freeze lines single or dual 3/8" - 1-1/2" through 3/8" to 8.00". The Accu Freeze kit (AF-1000) Liquid Nitrogen Pipe Freezing System can freeze lines up to 12.00".

Question: Can any of these pipe freeze kits freeze lines containing glycol (anti-freeze)?

Answer: The bag-style freeze kits have a greater chance of freezing lines containing small amounts of glycol, but not within the freeze times listed. Knowing the concentration of glycol is hard to determine; consider the antifreeze in your car that came from the factory with a known percentage of antifreeze in the radiator, but who knows what percentage that is after years of use and adding fluids. Whenever dealing with glycol it is highly recommended that you obtain a sample of the line contents and perform a test freeze with the same type of pipe in a controlled environment. This test will help you determine how long it will take to get the line to freeze and how much CO2 will be needed to perform the freeze on the job site.

Question: When would I use Hot Dam Heat Compound?

Answer: Anytime you use pipe freeze equipment that places an ice plug inside the plug and need to solder or weld the repair you should use Hot Dam. It removes most of the heat that melts ice plugs and protects your freeze jackets or clamps so your job goes smoothly. YouCan reuse it over and over again saving you money vs. the spray gels.

Question: Do you have to use gloves when using Hot Dam Compound? Are there Harmful chemicals in this product?

Answer: The materials safety data sheet for Hot-Dam warns, “This product, used as intended, may cause temporary mild irritation to sensitive skin. Pre-existing skin and respiratory conditions may be aggravated by exposure." Use precautionary measures if you have sensitive skin or respiratory conditions, and wash hands thoroughly after handling this product.

Back to Top

Question: What can I use to repair solder joints on a 6" copper line?

Answer: We currently do not have a clamp specifically designed for this application. There are a couple of products that may work for this application, but we cannot guarantee their success. If you are willing to take the chance on a nonreturnable item, call us to discuss the products that may work.

Question: Does the Insta-Clamp work for all copper solder joint leaks?

Answer: Yes, for the sizes available 1/2" thru 4.00" it stops leaks on 45’s, 90’s Couplings and Threaded Adapters.

Question: Can you fix a pin-hole leak with an Insta-Clamp?

Answer: Yes, the approximate 2.00" of gasket on the pipe side can be placed directly over the hole and sealed.

Question: Do you have PowerSeal 3425 Repair Clamp sizes just for copper pipe leaks?

Answer: Yes, these come in 8.00" and 12.00" widths for 3/4" thru 8.00" copper pipe leaks.

Question: Why does the PowerSeal 3425 Repair Clamp have a full circle gasket?

Answer: This eliminates electrolysis that occurs on copper pipe.

Back to Top

Product Description: Repair Couplings are used to permanently join two pieces of pipe together that is too difficult to be joined together by a welded or glue fitting. They normally use a full circle gasket and come in narrow to extra wide widths. They are many used in underground applications. See the JCM 101/102 Universal Repair Coupling.

Back to Top

Question: What are these for?

Answer: They are for repairs on longitudinal and circumferential breaks on critical service lines. They help eliminate shut-downs, draining the system and service interruptions.

Question: What is the difference between the two styles of Mechanical Joint Repair Sleeves you offer?

Answer: The JCM 114 Mech Jt Split Pipe Repair Sleeve is for permanent repair of straight runs of cracked or split Cast Iron pipe. These are used on severe breaks in cast iron pipe and are made to order. They are made to order to your exact specifications. The JCM 114 MJ Bell Pipe Repair Sleeve is for permanent repair of cast iron bells, split or leaking couplings and weld joints. These are used on joint leaks that can’t be fixed because shutting-down or draining the system is not available as an option or too expensive. They are made to order to your exact specifications.

Question: Can they make my size?

Answer: Yes, they can almost any size and dimension needed as log as you provide the required information such as type of pipe, pipe OD, required length, line content, line pressure and finish coating required.

Back to Top

Product Description: Cast Couplings use a more vertical type seal than a repair coupling. They too are used for permanently joining pipe when a welding or glue fitting is too difficlt to work. See the Powerseal PowerMax 3506 , the Powerseal PowerMax 3506 LB , JCM 202 or the JCM 204.

Back to Top

Product Description: See the JCM 800 Series Water Hammer Surge Suppession

Back to Top

Question: Do you have a metric OD tape measure?

Answer: Yes. Our 24" OD tape does have both centimeters and 100th’s of inches on the diameter side of the tape.

Back to Top

Question: What is the temperature rating of the Jet Swet plumbing plug?

Answer: Although the Jet Swet plumbing plugs to not have a specific temperature rating, the gasket material is a blend of silicone an NBR gasket material which is made to tolerate the heat they would endure from soldering the line which they are plugging. The contents of the line would rarely be an issue, and if the concern is damaging the gasket, you can always apply our hot dam heat stopping compound.

Question: How do I properly use a Jet Swet? How long will my repair take?

Answer: The Jet Swet is used by first turning off the active water pressure at the street, opening the faulty valve (if it won’t open, most plumbers just cut the valve off), inserting the Jet Swet through the draining water stream, through the valve or virgin pipe, compressing the Jet Swet gasket and instantly shutting off the water (up to 65 Lbs.!). Now the plumber can immediately repair the pipe or valve, right over the Jet Swet tool! Once the Jet Swet is stopping the water, you can solder on a new FULL–PORT or gate valve, right over the Jet Swet . If your repair requires you to solder on a restrictive valve, from which the Jet Swet cannot be removed, instead of soldering on a regulatory valve, you solder a male nipple onto the pipe over the Jet Swet TM, remove the Jet Swet from the pipe and then just thread on any “threaded" regulatory valve you want. Close the valve and you are done! Your repair should be completed in 10 to 15 minutes!

Question: What repair parts do you make for the Jet Swet?

Answer: The only repair part we make is for the only part that could ever go bad: the gasket. We make a replacement gasket for every size tool. We also sell a repair kit called the 1751 which is a kit of all the nuts, washers and gaskets to repair one each of the 1/2", 3/4" and 1.00" Jet Swets for those of us who have a tendency to loose small parts.

Question: Do you make custom or longer Jet Swets?

Answer: Yes. They are special order and take a bit of time to make, but Jet Swets can be made as long as 50″. Please call well in advance of these types of jobs so we can make one for you. It takes roughly about 3 weeks.

Question: Do the larger sizes come in kits?

Answer: No, the 2-1/2″, 3.00″ and 4.00″ Jet Swets, whether “normal" style or Flo-Thru are just so big, that they could not go in any case that you would want to carry around. They are sold “Bulk" style, meaning it is just the too1s by itself.

Question: What is a Jet Swet Flo-Thru Tool?

Answer: Flo-Thru Jet Swets were designed to help in the situation where you are using a big Jet Swet in big pipe such as 2-1/2″ 3.00″ and 4.00″. The pressure becomes so intense that we designed a tool that has a 1/2″ cavity down it’s center to allow you to drain water or add air to the system through the tool while actually doing the repair! You can connect a standard garden hose to the back end of the tool to drain the system to a sink or floor drain. These tools are so popular, people have almost altogether stopped buying the “normal" style 2-1/2″, 3″ and 4″ Jet Swets. They are so popular in fact, that we are coming out with Flo-Thru versions of all our smaller sizes 1/2″ through 2″ to add to the Flo-Thru collection.

Question: Do I need to shut off the water to the system in order to use a Jet Swet?

Answer: Yes.

Question: What if I have more than 65 lbs of pressure in the system?

Answer: Yes, as with any repair job, Jet Swets are to be used while the water pressure is turned off. Jet Swets are designed only to hold back the draining and siphoning water that keeps you from doing your repair. Many times, the draining and siphoning water still build up more than 65 lbs of pressure. In these cases, plumbers have told us the easiest way to get the pressure below 65 lbs is to open a bunch of sink and tub fixtures in the system until it is safe to use the Jet Swet.

Question: What kind of maintenance should I do on the tools?

Answer: If the gaskets ever get torn, burned or misshapen they will need replacing. Secondly, you should re-grease the threads under the middle “tension" nut. This can be done by simply disassembling the tool from the gasket end. We recommend using a non-water soluble grease such as the “Boat and Marine Grease" sold at your favorite auto-supply shop such as Pep-Boys.

Question: How do I change the gaskets?

Answer: Jet Swets washers look the same from the outside as any other washer you have ever seen, but on the inside, they are quite different. It is therefore important, when replacing parts or servicing the tool that you keep track of the washers and the order in which they were removed from the tool. The tool can be disassembled using a normal wrench. Make sure you replace the gasket with a correct sized gasket. Each tool is calibrated to use a specific gasket with specific properties. By using incorrect gaskets on your tool, you not only void the warranty, but you run the risk of damaging the tool, the pipe system or the tool not working.

Question: How far into the pipe should the Jet Swet gasket be inserted?

Answer: The only part of the tool susceptible to heat damage is the gasket at the end of the tool. It is made of a special silicon/EPDM composite that withstands extreme heat, but you cannot solder right over it. We recommend placing the tool at least 5 inches into the pipe, away from the soldering site. If the job does not permit for this rule, you can use our heat stopping compound Hot Dam. If the gasket is unavoidably damaged, we make replacement gaskets very cheap and easy to replace.

Question: How many pounds of pressure can Jet Swets handle?

Answer: Every Jet Swet is calibrated to hold a maximum of 65 PSI. We have heard of plumbers using them on much higher-pressure situations, but at that moment they forfeit our warranty, and we forfeit any liability.

Back to Top

Question: Do you offer ball valves that are not listed on your web site?

Answer: Yes. We have the full line of Jomar products available, but since there are so many products, we are not able to list them at this time. Call us and let us find what you are looking for.

Back to Top

Question: Couldn’t I just use air to test my fittings before performing a tap?

Answer: The manufacturers of our tapping sleeves and tapping saddles highly recommend hydrostatic testing since water and air behave differently. If a saddle fails an air test and is sent back to the manufacturer for a return, when they test it using water and it passes, a refund will not be issued. It makes sense to test with the contents of the pipe, or at least similar contents. View our hydrostatic pumps now.

Back to Top

Product Description: There are many types of pipe cutters. They are designed for small or large pipe and for different types of pipe such as Steel, Copper, Plastic or Soil. There are units designed to cut multiple pipes at the same time with a special chain design, electric band saw styles for quick cuts of larger pipe and small hand held units. See the Kwik-Snap Chain Style Soil Pipe Cutter.

Back to Top

Question: If I need to clamp at two locations, do I need to buy two of these shut off tools?

Answer: No. You can purchase additional clamps that can be left on the line without the machine. See our accessories page.

Question: Can you use the Pipe Shut Off Tools on Steel?

Answer: No, Please call us for units that can shut-off steel pipe.

Back to Top

We will respond to your question as soon as possible. Hours of operation are Monday through Friday 7 AM to 5 PM PST.

Back to Top

Contact

Toll Free: 1-877-747-3626

Office: 1-530-221-3600

Corporate Office: 1-925-439-7975

For questions regarding our products:

Sales@PipeManProducts.comRequest a Quote:

Quote@PipeManProducts.com